Computational Fluid Dynamics

Stirling Dynamics’ CFD capabilities to support design, analysis and optimisation activities in multiple industries, resulting in improvements and long-term benefits for efficiency, design, and safety.

Stirling Dynamics CFD Capability

Combined experience includes applications across multiple technology sectors – Aerospace, Marine, Turbomachinery.

Stirling Dynamics CFD capability provides powerful prediction methods for complex 3D fluid dynamics problems, as part of design, analysis and optimisation activities for various applications across many industries.

Our extensive experience ranges from carrying out short-term modelling tasks (e.g. provision of initial performance data for early-phase design) through to long-term support programmes covering process validation, iterative design optimisation, data generation for other capability activities, certification support, and future upgrades.

Aerospace

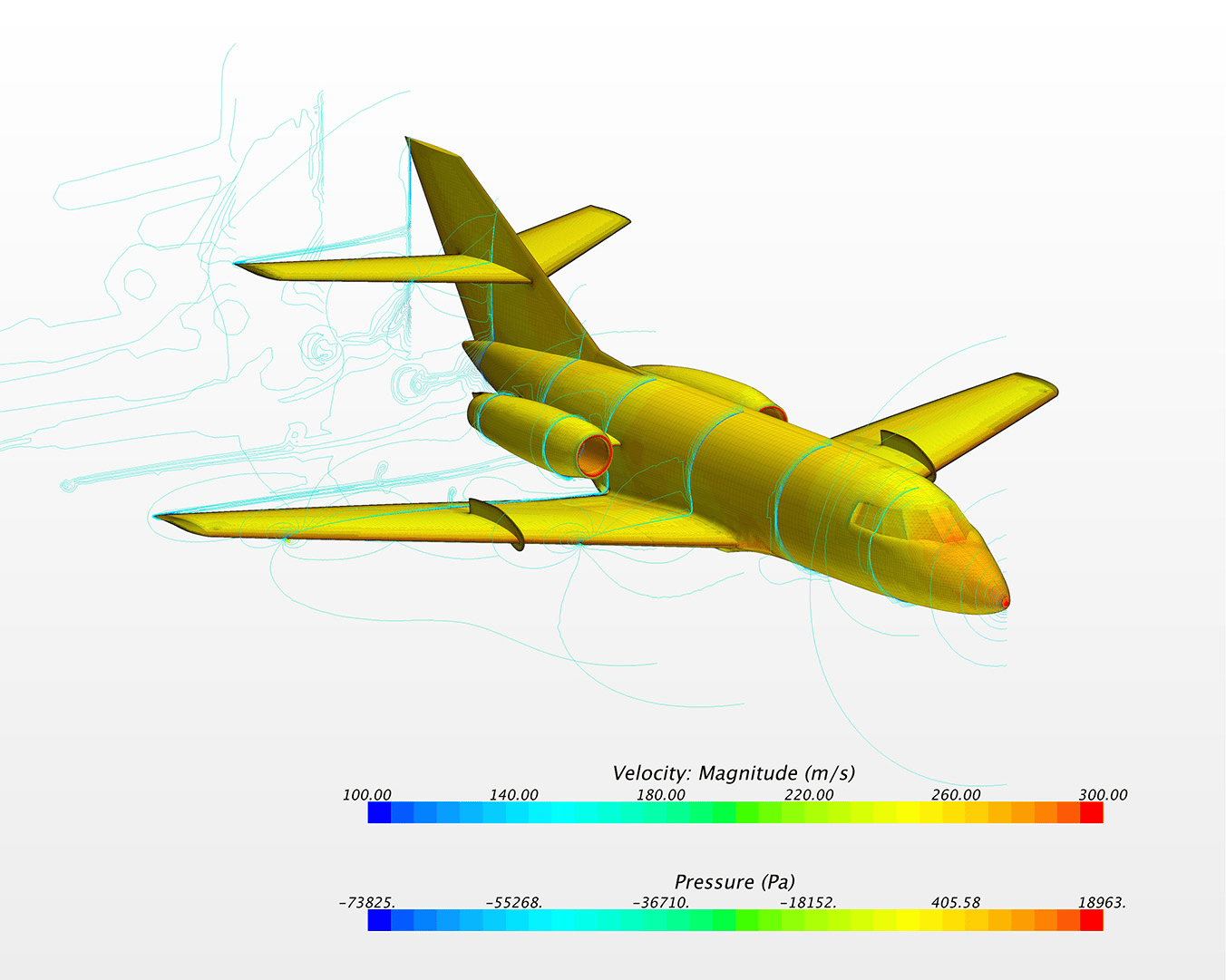

Stirling Dynamics offers CFD capability to support new aircraft programmes, aircraft modifications, flying body design and aircraft reverse engineering programmes.

View Our Aerospace Capability

Marine

Stirling Dynamics is skilled in modelling multi-disciplinary systems and multi-body system motion dynamics across the marine sector.

View Our Marine Capability

Aircraft Modification

Modelling and analysis

Stirling Dynamics can provide fluid dynamics modelling and analysis for retrofitted modifications to aircraft (including fuselage modifications), ranging from cameras, belly plinths and nose extensions through to blister fairings, radomes, sensor turrets and ISR system equipment.

With our efficient modelling methodology, we can provide a highly focused evaluation of platform performance, stability and control and aero loads data for design and certification purposes.

We can also offer wind tunnel comparisons, trade studies and design optimisation studies for external surfaces and attachments.

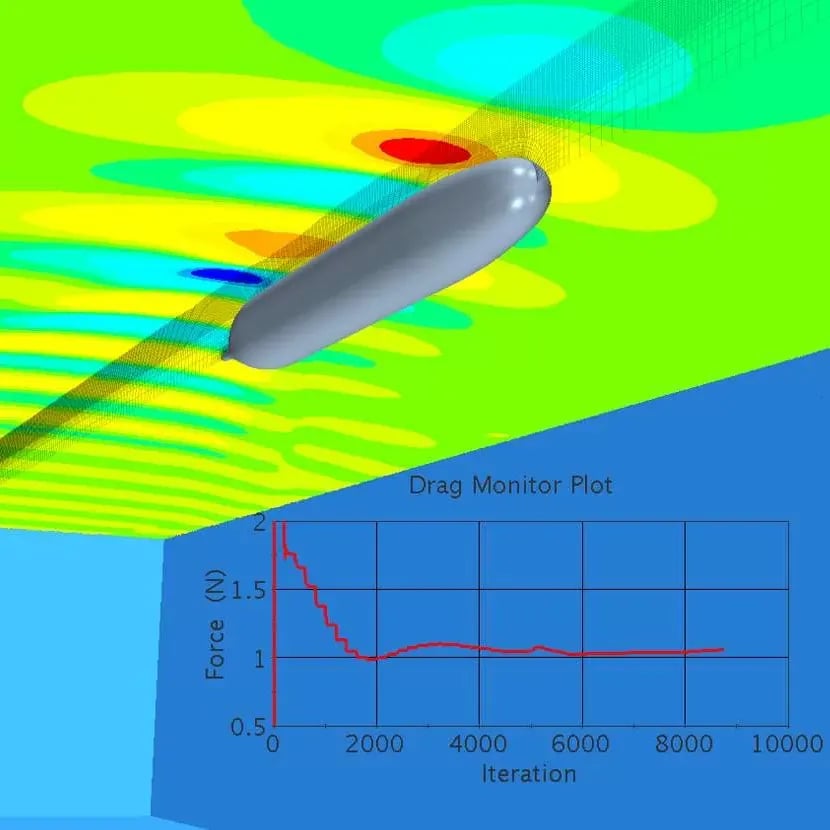

Electronic Decoy Design

Design, analysis and optimisation of fast-jet Expendable Active Decoy (external body)

We are capable and experienced in:

- Steady-state subsonic and supersonic modelling used to develop and down-select concept designs (including potential control surfaces)

- Dynamic fluid-body interaction (DFBI or FSI) modelling on mature geometries for in-depth performance analysis at range of Mach, altitudes, ejection angles

- Additional DFBI modelling of customer trials to recreate test conditions on final designs

In-House High Performance Computing (HPC) Technology

help with reverse engineering, validation of aircraft models and assessment of aerodynamic performance

Stirling Dynamics utilises in-house HPC resources, providing highly secure, readily available computing capacity. Our CFD offering complements our existing simulation and modelling capabilities. Our toolset industry experience includes main commercial solvers such as ANSYS Fluent & CFX as well as Siemens Star CCM+.

Hull Modification Analysis

TRUSTED PERFORMANCE PREDICTIONS FOR BETTER DESIGN DECISIONS

Our CFD capability can be used to analyse the impact of hull modifications to surface and submerged platform hydrodynamic performance, as well as assessment of design changes and configuration updates.

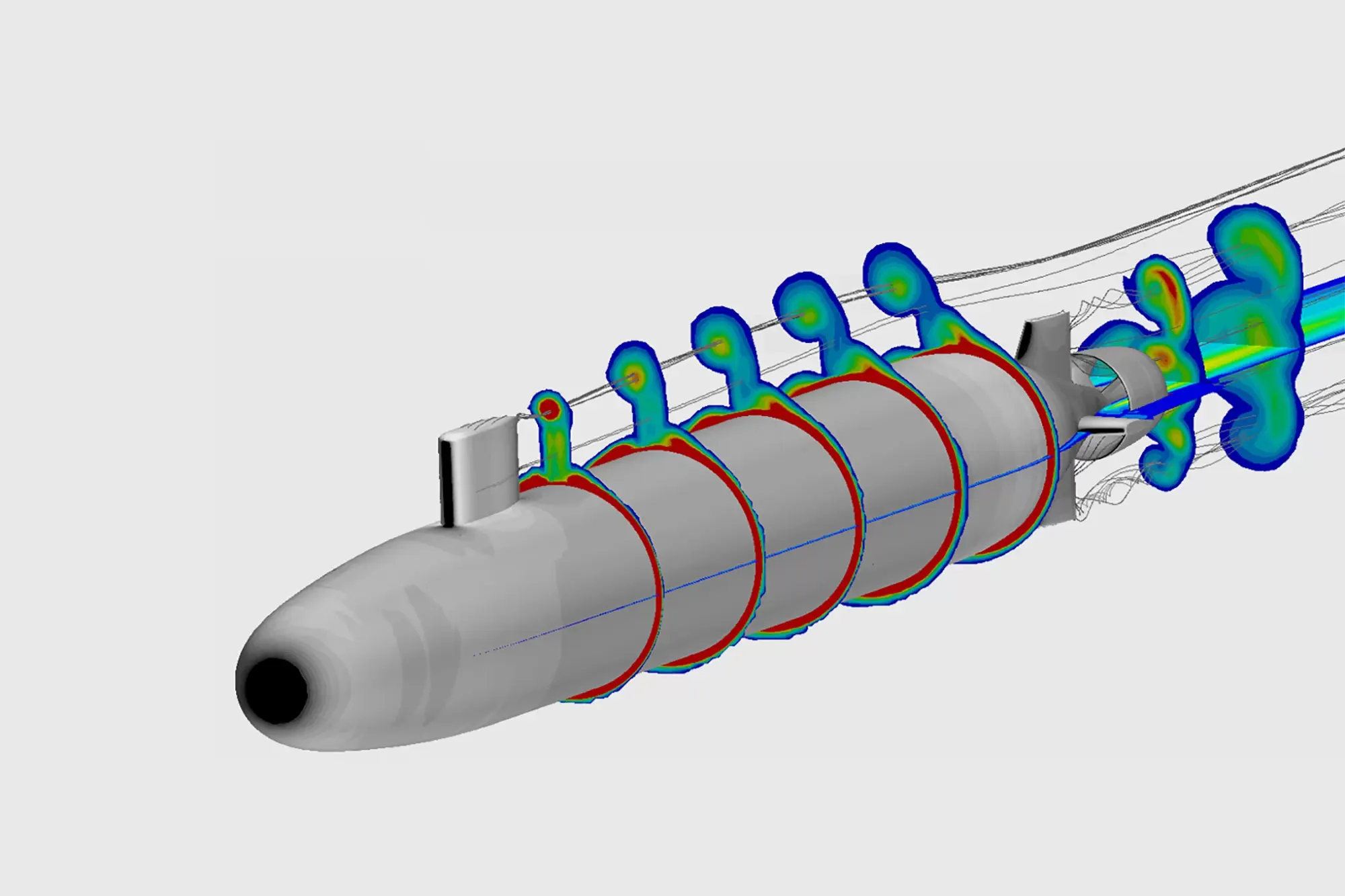

Towed Array Modelling

MODELLING COMPLEX MULTI-BODY SYSTEMS

Stirling Dynamics has a long history of modelling dynamic systems in the marine domain, including a diverse range of surface platforms, sub-surface platforms and cable towed vehicles/devices. Our CFD capability has been used to complement this offering by predicting hydrodynamic performance inputs to dynamic modelling as well as analysing more complex off-design / transitionary operating conditions.

.webp)

Advanced Modelling Environments

FROM INDUSTRY-STANDARD CAE TOOLS TO BESPOKE MODELS

We can implement our models using a range of modelling environments from industry-standard CAE tools to bespoke models in MATLAB/Simulink, to standalone real-time software models for hardware-in-the-loop (HIL) testing and training simulations.

Related Case Study

Do you have a specific project in mind?

Let’s discuss your requirements.

Please use the form below to contact us: