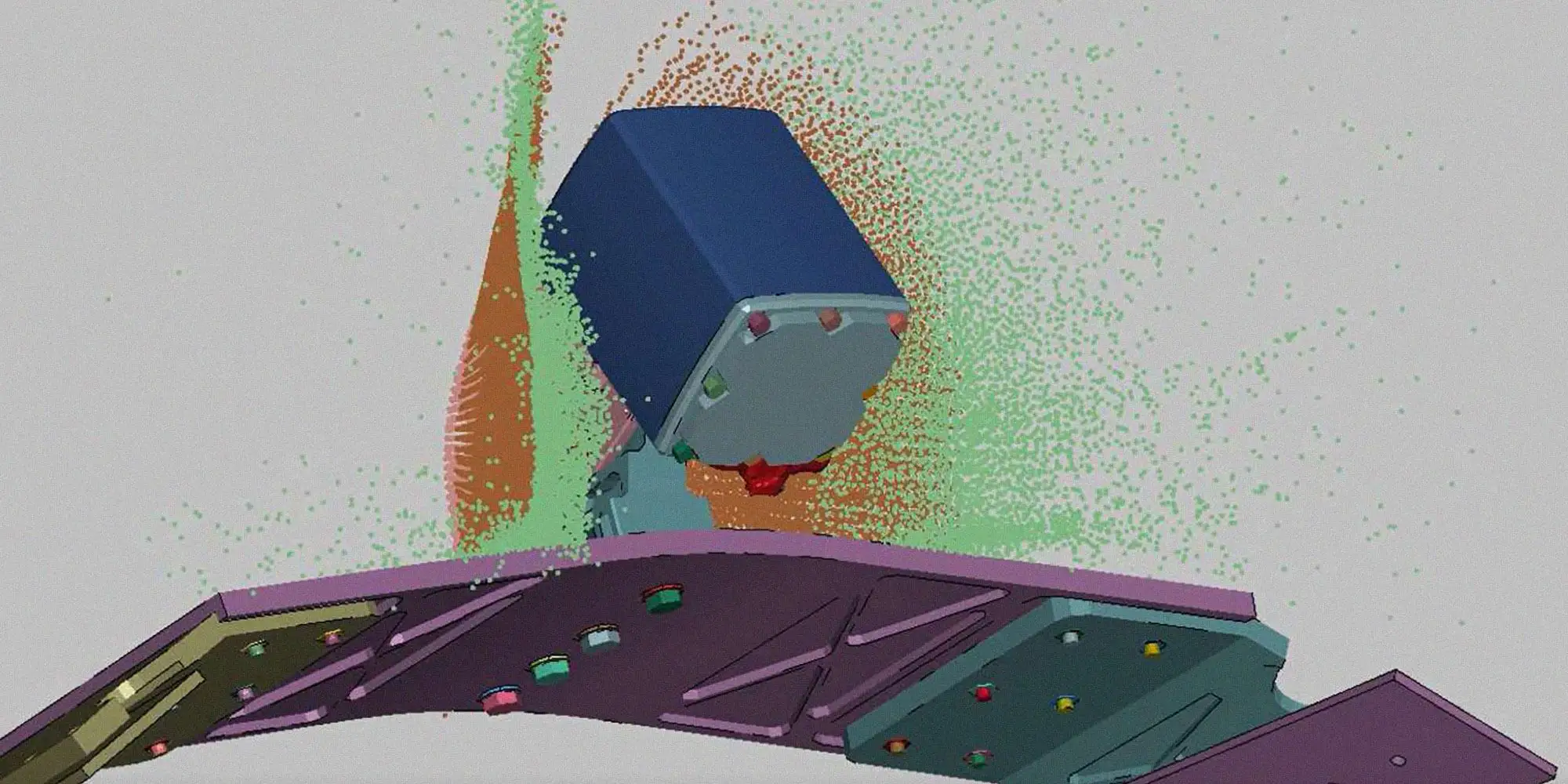

Helicopter Nose Bracket Bird Strike

Our customer, Helitune, is a market leader in the design and manufacture of Rotor Track & Balance equipment. The equipment and its supporting...

Question 1. Can you describe your area of expertise?

My area of expertise is rotor aeromechanics. Rotor aeromechanics is concerned with the engineering of efficient rotor/propeller systems to meet the vehicle propulsion requirements, manage, and mitigate steady and vibratory loads, ensure propulsion system stability and that the aircraft handling is predictable, and minimise propulsion system noise.

Question 2. What was your experience before joining Stirling Dynamics?

I’ve worked in aerospace for 25 years. I studied for a PhD at Bristol University (UK) and have worked as a post-doctoral fellow at Ulm University (Germany). In 2000, I joined the Rotor Aeromechanics Department at Westland Helicopters (now Leonardo Helicopters) and was fortunate to start work on the fourth-generation British Experimental Rotor Programme (BERP IV) now in production on Leonardo AW159 and AW101. I progressed to become the technical lead of a retrofit rotor design, transferring BERP IV technology to a legacy aircraft, and after that, I was the technical lead for various future rotor system projects, including setting up and leading the €20M, JTI, Clean Sky, GRC, Innovative Rotor Blades programme.

In 2010, I started up a consultancy to provide aeromechanics engineering and software development services. Our work included roles as independent technical evaluations for fixed-wing and rotary-wing aircraft certification; we developed analytical methods for wind turbine and propeller performance, loads and stability analysis; and we provided consultancy for UK advanced rotor design studies and overseas design projects. Last year, I joined Stirling Dynamics to grow the business in the rotor aeromechanics sector.

Question 3. What kind of projects do you work on?

My work includes the design and analysis of rotor systems and the analysis of vehicle performance and loads. Perhaps the most rewarding part is contributing to the development of Stirling’s analytical methodology to tackle the likely airworthiness certification requirements of these new, and varied, eVTOL vehicle concepts.

Question 4. Would you agree then that there’s been a shift from conventional to unconventional aircraft?

Conventional aircraft continue to provide most of the work for our Loads and Aeroelastics group and this is also increasing in demand. These projects include loads assessment of new aircraft, modifications to existing aircraft, and aircraft change of use. In addition, we have regular demand for our landing gear design and analysis services. However, recently, there has been a growing demand for our services from the emerging eVTOL sector.

The growth in our workload, from the conventional and new aerospace sectors, has been matched by an expansion of our team. This has provided the opportunity to extend the expertise we can offer. One of our new offers is Rotor Aeromechanics, which is a great opportunity for me.

The growth in our workload, from the conventional and new aerospace sectors, has been matched by an expansion of our team.

Question 5. What potential issues will these eVTOL aircraft need to overcome?

The challenges of designing multi-rotor eVTOL are split into two categories: tilt-rotor requirements and fixed-rotor requirements.

A tilt-rotor vehicle takes off and lands with the rotors in the helicopter mode but must rotate them, and change their rotational speed, to use in a propeller configuration for forward flight. This transition phase is the most demanding condition for the rotor throughout the aircraft flight envelope, and this is also the most technically challenging to simulate, not least of all because the blade structural response is critical to simulate system performance, loads and stability. Designing the rotor system for the transitory conditions, to ensure they have low vibration for passenger comfort and confidence and are stable and have predictable handling characteristics for the safety of flight, will be crucial for the commercial viability and airworthiness of the vehicles.

Designing the rotor system for the transitory conditions, to ensure they have low vibration for passenger comfort and confidence and are stable and have predictable handling characteristics for the safety of flight, will be crucial for the commercial viability and airworthiness of the [eVTOL] vehicles.

In contrast, a fix-rotor vehicle takes off, flies forward, and lands with its rotors in helicopter mode. The key difference with a conventional helicopter is that the rotor systems do not have cyclic control of the blade pitch angle, which is conventionally used to manoeuvre the vehicle. Instead, multi-rotor vehicles manoeuvre by changing the relative magnitude of thrust between the rotors, and this is achieved by changing the relative rotational speeds. This means that the eVTOL rotor systems are less complex, lower weight and lower cost to produce and maintain; as well as generally being electric. The compromise, however, is the design challenge of managing an imbalance between the rotor loads on the advancing and the retreating sides of the rotor. This effect produces high vibratory loads at the hub, and this vibration increases with increasing flight speed.

For both vehicle types, as the control of the vehicle is through variable rotor speeds, the rotor systems and airframe must be designed to avoid excitation of the structural natural resonance frequencies throughout the flight envelope and for any system failure cases (including software). This safety of flight requirement is a new challenge in aerospace engineering, both in calculating system fatigue life and in analysing failure cases.

My advice is to invest early in exploring solutions that are pertinent to the engineering and certification challenges of your vehicle’s rotor mode of operation.

Stirling Dynamics has been supplying technical engineering expertise to the aerospace market for over 35 years. Our services support new aircraft designs and modification programmes, for rotary-wing platforms in both civil and military arenas. Click here for more information on how Stirling can support your rotary-wing programme.

Our customer, Helitune, is a market leader in the design and manufacture of Rotor Track & Balance equipment. The equipment and its supporting...

We are delighted to be exhibiting once again at the Farnborough International Air Show (FIA 2024). Joining our parent company, Expleo, in Hall 1,...

In support of the Korean Light Utility Helicopter (KLUH) programme, our client, Hanwha Corporation, was faced with the challenge of designing and...